Powder Distribution Mechanism Development

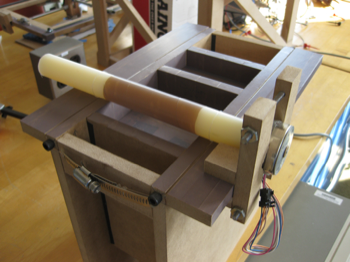

My first powder distributor.

The print powder management hardware had to both function as the z-axis of the 3D printer and solve the problem of print powder storage and distribution. I attempted to employ the same linear motion system from my XY translation system to create a rolling powder distributor that would spread the powder and lightly compact it in the process. The roller approach was disastrous. The fresh powder from the feed piston compacted and stuck to the roller while surplus powder overflowed off of the feed piston and onto the roller supports, quickly jamming the roller.

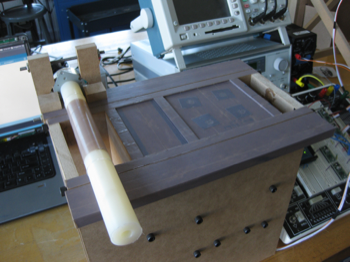

Left: testing a wedge-wiper mechanism. Right: build-up of print powder on a timing pulley.

I quickly opted for a wiper-based mechanism instead. My first test of the mechanism delivered beautiful, smooth new layers of powder. However, after rigorous use, the timing belts and pullys got gummed up with compacted print powder, causing the driving stepper to strain when a timing belt became mis-aligned.

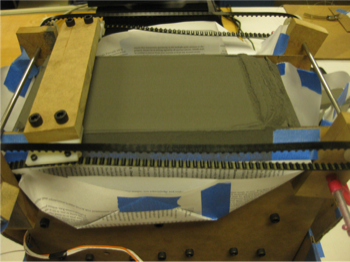

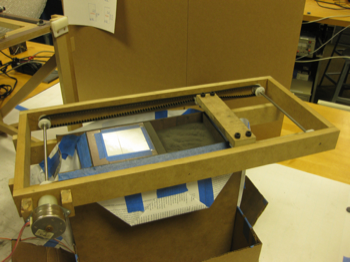

Left: the powder pistons and surplus powder hoppers. Right: the revised wedge-wiper powder distributor mounted.

I built a large and more modular powder distributor because the first wedge-wiper prototype was built with extra timing belts that couldn't span the whole powder piston system. The revised wedge-wiper sat on the power piston system and could be easily removed to make it easier to extract completed prints.

blog comments powered by Disqus