Laser Shutter Mechanism and Optics Mount

I ordered two fiber-coupled 2 Watt IR lasers from eBay for $99 apiece. The output of a fiber carrying last light is essentially a wildly divergent point source, so my first task was to collimate the laser output by dumping it into the end of a microscope objective. I fabricated a simple jig to facilitate precise three-dimensional positioning of the fiber terminus in front of a microscope objective. I directed the output of the objective lens onto a wall and observed the spot with my cell phone's camera (nearly all digital cameras pick up IR). By observing the changes in spot size, I was able to determine optimal spacing between the fiber terminus and several different microscope objectives.

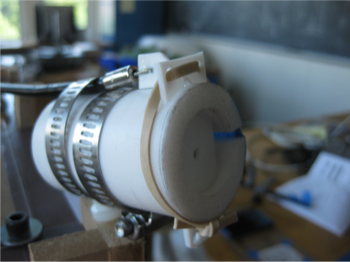

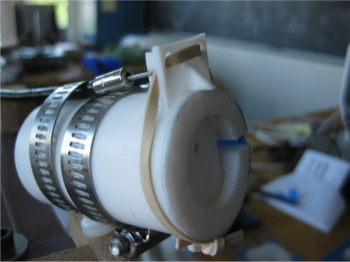

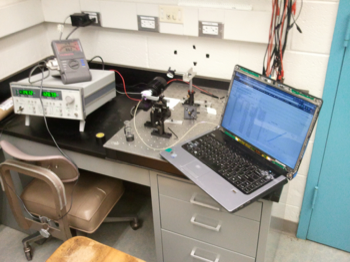

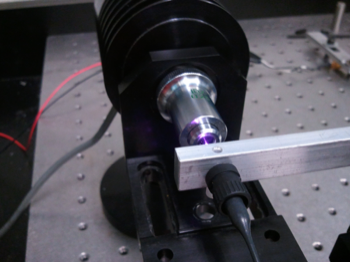

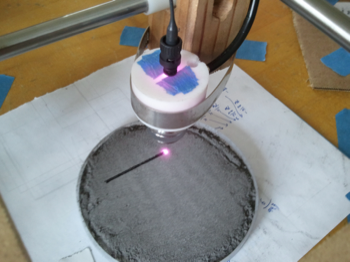

Left: my set up for determining optimal terminus-objective spacing. Right: detail of the laser emitting into the objective. The resulting beam is here directed into a power meter.

My first laser shutter mechanism was simply a piece of bicycle brake cable wrapped in Teflon tape. A solenoid actuated the cable, driving the Teflon-wrapped end between the fiber terminus and the objective, preventing the laser from exiting the optics mount. Oil or grit on the Teflon led to troubles with off-gassing Teflon condensing on the fiber terminus.

This optics mount's performance gradually declined as residue built up on ht fiber terminus.

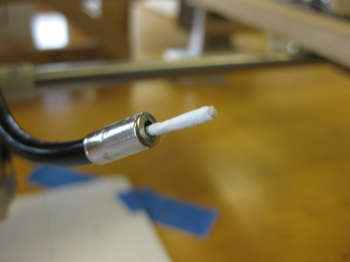

The shutter end of the brake cable, before and after use.

I machined my next optics mount again out of Teflon and implemented a more reliable shutter mechanism.

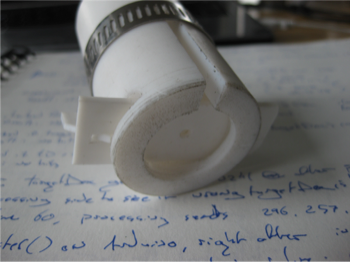

The revised optics mount.