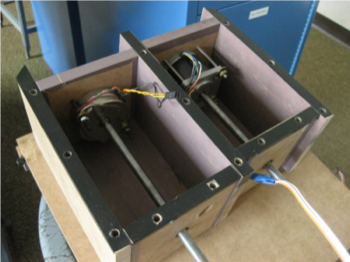

Powder Distribution Hardware

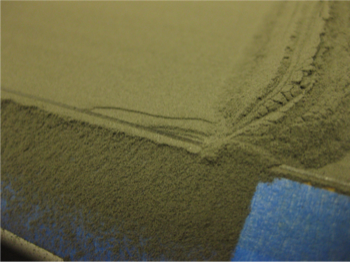

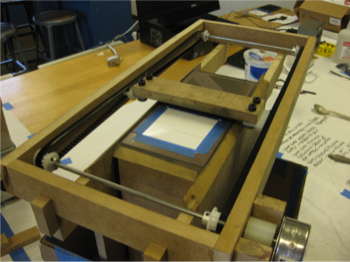

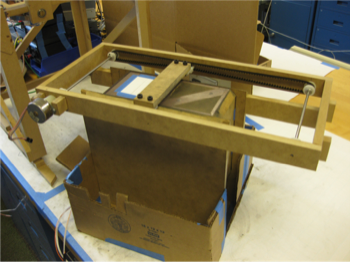

The powder distributor on top of empty feed and print pistons.

The power distributor uses a stepper to drive two timing belts to which a Teflon-coated wedge is secured. A feed piston loaded with print powder advances at the beginning of each new layer sequence. The print piston recedes 0.3 mm and then the wiper sweeps across the feed piston and transfers a thin layer of powder onto the print piston. Surplus powder falls off the edges of the piston housing into simple paper hoppers.

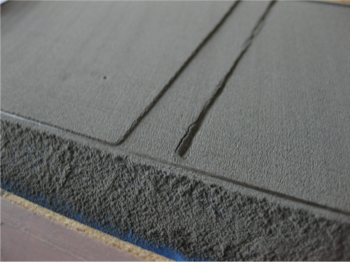

Left: the feed and print pistons. Right: the Teflon-coated cover that bolts down to enclose the pistons

The feed and print pistons are each driven by a stepper motor secured to the underside of each piston platform. The stepper motors are directly coupled to lead screws that turn in a captive nut to provide very precise Z-positioning.